Tired of Your Venturi Valve?

Enhance Safety, Sustainability and Efficiency in Your Critical Environment

The demand for more efficient, reliable, and cost-effective airflow control solutions has never been more pressing for decision-makers in critical environment design management. Among the myriad of options available, two distinct choices have emerged at the forefront of airflow control: the traditional venturi valve and the AccuValve® by Accutrol.

While Venturi valves have been a staple in the industry since the 1960s, the AccuValve is an innovative product that utilizes newer technology that offers a suite of advanced features tailored to meet the rigorous demands of today’s critical environments.

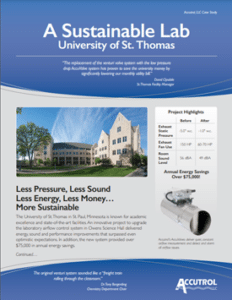

A common praise of the AccuValve is noise reduction. “The original venturi system sounded like a freight train rolling through the classroom.” – Dr. Tony Borgerding Chemistry Department Chair at St. Thomas

This article breaks down why leading facilities worldwide are making the switch to AccuValve. From award-winning projects like Harvard University’s Science and Engineering Complex to energy-conscious projects such as the University of St. Thomas saving $75,000 annually in energy cost by replacing their venturi valves with the AccuValve. The shift towards AccuValve is a testament to its superior design, efficiency, and adaptability.

What is A Venturi Valve?

In critical care environments, venturi valves are mechanical airflow devices created with the intention to control and manage airflow. The venturi valve uses a spring and cone mechanism that relies heavily on fan pressure to operate; thus, the idea of low pressure is not considered when using this technology. Venturi valves were the standard and default choice for air valve installation for many years by engineers and building owners.

Why is The Desire for Low Airflow Pressure Important?

Energy savings is one key reason. High pressure requires excessive fan horsepower which results in higher electricity bills. A simple analogy is cars and gas prices. If you desire to save money as a commuter, would you prefer a car that receives 15mpg, or, 50 mpg? Many critical environments are running 24/7 and use significantly more energy than an average building. Increased attention to energy waste has built a demand for manufacturers to be innovative.

Can You Safely Operate with Low Airflow Pressure in Critical Environments? The Low-Pressure Airflow Myth

The antiquated industry myth claims, “Air valves in critical environments cannot operate safely at low air pressure.” This appears to be true with older technology such as the venturi valves, but not AccuValve. Since venturi valves require a tremendous amount of air pressure and hence fan horsepower to operate properly, there is no way for them to circumvent their use of fan energy for pressure independence. These factors can explain why people would be skeptical of low-pressure devices airflow being safe, or even possible. Read a detailed breakdown of the low pressure myth here

The antiquated industry myth claims, “Air valves in critical environments cannot operate safely at low air pressure.” This appears to be true with older technology such as the venturi valves, but not AccuValve. Since venturi valves require a tremendous amount of air pressure and hence fan horsepower to operate properly, there is no way for them to circumvent their use of fan energy for pressure independence. These factors can explain why people would be skeptical of low-pressure devices airflow being safe, or even possible. Read a detailed breakdown of the low pressure myth here

AccuValve Can Offer Safe High-Speed Control at Low Duct Pressures

High-speed control even at low duct pressures is one of the features that sets AccuValve apart from traditional venturi valves. This capability is rooted in its innovative design and the use of advanced sensor technology that measures airflow. Unlike mechanical systems that rely on high pressures to function, the AccuValve utilizes closed-loop control with true airflow feedback, ensuring precise regulation of airflow without the need for excessive fan energy. This method not only enhances the valve’s responsiveness and accuracy but also significantly reduces energy consumption. The AccuValve’s ability to maintain optimal performance in low-pressure environments is crucial for modern critical environments, where safety, efficiency, and sustainability are paramount. By leveraging state-of-the-art technology, the AccuValve delivers unmatched control, showcasing Accutrol ‘s commitment to pioneering solutions that meet the demands of contemporary airflow management.

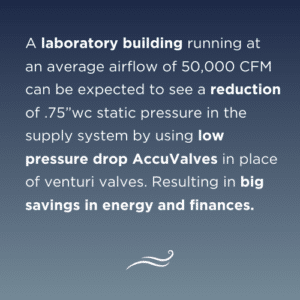

Lab Saving Energy Stats With Accuvalve

The Top 10 Reasons to Choose AccuValve Over the Venturi Valve:

- Energy Efficiency: AccuValve operates effectively at low pressures, significantly reducing energy consumption and costs.

- Advanced Airflow Measurement: It continuously measures airflow, ensuring precise control and safety.

- Design Innovation: Utilizes a “clean sheet” design focused on modern requirements, not constrained by outdated technologies.

- Pressure Independence: Achieves true pressure independence without excessive fan energy.

- Compliance with Standards: Designed to meet and exceed ASHRAE 90.1 standards, ensuring broader compliance and system efficiency.

- Maintenance-Free Operation: Requires no recalibration, cleaning, or maintenance, ensuring long-term reliability.

- Safety and Alarm Notifications: Provides alarms for inadequate airflow, enhancing safety in critical environments.

- Reduced Noise Levels: Offers quieter operation, contributing to a more pleasant and less disruptive environment.

- Flexibility and Compatibility: Can be easily integrated and retrofit with existing building automation systems, offering greater system design flexibility.

- Cost Savings: Beyond energy savings, reduces potential costs related to maintenance, system upgrades, and non-compliance issues.

Conclusion

In the quest for optimized airflow control within critical environments, the choice between traditional Venturi valves and Accutrol ‘s AccuValve is pivotal. The article above delineates the advantages of adopting AccuValve over its dated counterpart, the venturi valve. Emphasizing energy efficiency, precise airflow measurement, and safety, AccuValve emerges as the superior choice for modern critical environments, including hospitals and laboratories.

AccuValve’s design innovation allows for high-speed control at lower duct pressures, significantly reducing energy consumption without compromising on safety or efficiency. With a focus on sustainability, compliance with contemporary standards, and maintenance-free operation, AccuValve not only addresses the challenges posed by traditional systems but also aligns with the future of environmental management.

If you’re interested in learning more, please reach out to your nearest rep for more info or a demo: https://accutrolllc.com/airflow-products-rep-locator/