AccuValve® vs. Venturi Valve – Top 10 Reasons for The Best Choice in the Future of Airflow Control

The demand for more efficient, reliable, and cost-effective airflow control solutions has never been more pressing for decision makers in critical environment design. Among the myriad of options available, two distinct choices have emerged at the forefront of airflow control: the AccuValve by Accutrol and the traditional mechanical venturi valve.

While Venturi valves have been a staple in the critical environment industry since the 1980s, the AccuValve represents a leap into the future, offering a suite of advanced features tailored to meet the rigorous demands of today’s critical environments.

This article breaks down why leading facilities worldwide are making the switch to AccuValve. From award-winning projects like Harvard University’s Science and Engineering Complex to energy-conscious projects such as the University of St. Thomas saving $75,000 annually in energy cost by replacing their venturi valves with the AccuValve. The shift towards AccuValve is a testament to its superior design, efficiency, and adaptability.

Here is the top 10 list, with a more thorough breakdown below:

The Top 10 Reasons to Choose AccuValve Over the Venturi Valve:

- Energy Efficiency: AccuValve operates effectively at low pressures, significantly reducing energy consumption and costs.

- Advanced Airflow Measurement: It continuously measures airflow, ensuring precise control and safety.

- Design Innovation: Utilizes a “clean sheet” design focused on modern requirements, not constrained by outdated technologies.

- Pressure Independence: Achieves true pressure independence without excessive fan power, using microprocessor based closed-loop control.

- Compliance with Standards: Designed to meet and exceed ASHRAE standards, ensuring broader compliance and system efficiency.

- Maintenance-Free Operation: Requires no scheduled recalibration, cleaning, or maintenance, ensuring long-term reliability.

- Safety and Alarm Notifications: Provides alarms for inadequate airflow, enhancing safety in critical environments.

- Reduced Noise Levels: Offers quieter operation, contributing to a more pleasant and less disruptive environment.

- Flexibility and Compatibility: Can be easily integrated and retrofit with existing building automation systems, offering greater system design flexibility. This process includes our free award-winning Insight Software which enables users to configure devices to their specific requirements.

- Cost Savings: Beyond energy savings, reduces capital costs related to higher system pressures such as larger fans and fan motors.

AccuValve’s technology, energy savings, and enhanced safety features make it the preferred choice for modern airflow control in critical environments.

What is the AccuValve?

The AccuValve by Accutrol is an award-winning airflow control solution designed for critical environments requiring utmost precision and energy efficiency. Utilizing advanced sensor technology, the AccuValve offers high-speed control at low duct pressures, eliminating the need for high fan power typical of mechanical valves. Its innovative, pressure-independent operation is powered by a 24V supply and closed-loop control with true airflow feedback, ensuring accurate and reliable environmental conditions.

Why is Low Duct Pressure Important?

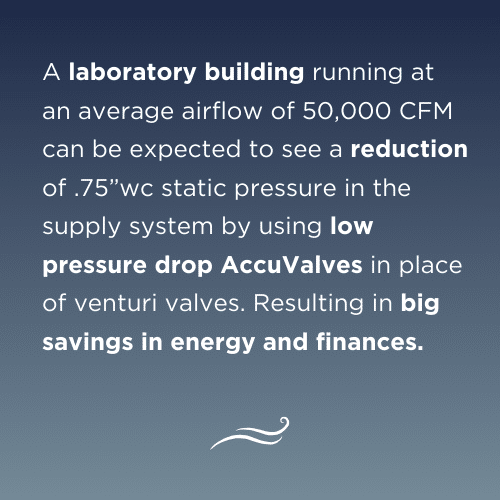

Energy savings is one key reason. The additional duct pressure required to operate the mechanical venturi valve adds considerable fan horsepower requirements. This translates to higher electricity bills not to mention larger fans and motors. So higher pressure operation costs the owner in both upfront capital cost as well as higher operating cost. Increased attention on energy waste has built a demand for manufacturers to be innovative toward energy saving devices.

Can You Safely Operate with Lower Duct Pressure in Critical Environments?

The simple answer is YES with the proper equipment. A major venturi valve manufacturer claims, “Air valves in critical environments cannot operate safely at low air pressure.” The examples that they give in the paper are with blade dampers and differential pressure airflow sensors. It is because of the limitation of simple blade dampers that Accutrol invented the AccuValve which combines a unique design using two chambers with Vortex airflow sensors and two blades operating in a bias manner. This enables high speed and most importantly stable control with duct pressure 1.0” to 2.0” lower than would be required for a venturi system. Adding to this advantage is actual airflow measurement in the AccuValve versus the antiquated mechanical venturi which only measures valve position – not airflow.

Since venturi valves are mechanical in nature and require a tremendous amount of duct pressure and fan horsepower to obtain their pressure independence, they cannot circumvent their requirement for higher fan energy. (A detailed breakdown of the low-pressure airflow myth can be found here.)

AccuValve Can Offer Safe High-Speed Control at Low Duct Pressures

High-speed control even at low duct pressures is a feature that sets AccuValve apart from older mechanical venturi valves technology. This capability is rooted in its innovative design and the use of advanced sensor technology that measures airflow. Unlike mechanical systems that rely on high pressures to function, the AccuValve utilizes closed-loop control for true airflow feedback, ensuring precise regulation of airflow without the need for excessive fan power. This method not only enhances the valve’s responsiveness and accuracy but also significantly reduces energy consumption. The AccuValve’s ability to maintain optimal performance in low-pressure environments is crucial for modern critical environments, where safety, efficiency, and sustainability are paramount. By leveraging state-of-the-art technology, the AccuValve delivers unmatched control, showcasing Accutrol’s commitment to pioneering solutions that meet the demands of contemporary airflow management.

Conclusion

In the quest for optimized airflow control within critical environments, the choice between older mechanical venturi valves and Accutrol’s AccuValve is pivotal. The article above delineates the advantages of adopting AccuValve over its dated counterpart, the venturi valve. Emphasizing energy efficiency, precise airflow measurement, and safety, AccuValve emerges as the superior choice for modern critical environments, including laboratories and healthcare.

AccuValve’s design innovation allows for high-speed control at lower duct pressures, significantly reducing energy consumption without compromising on safety or efficiency. With a focus on sustainability, compliance with contemporary standards, and maintenance-free operation, AccuValve not only addresses the challenges posed by traditional systems but also aligns with the future of environmental management.

If you’re interested in learning more, please reach out to your nearest rep for more info or a demo: https://accutrolllc.com/accutrol-airflow-control-products-rep-locator/